HELI-ARC FABRICATIONS

Custom Intercooler Fabrication | Welding & Fabrication Services | Production Welding | R&D Welding Services

Custom Fabrication Services |

Welding Services |

Break Form Services |

Band Saw & Cold Saw Services |

Lathe/Turning Services |

Milling Services |

Drilling & Taping Services |

Thread Repair Services |

Fixture Building Services

About

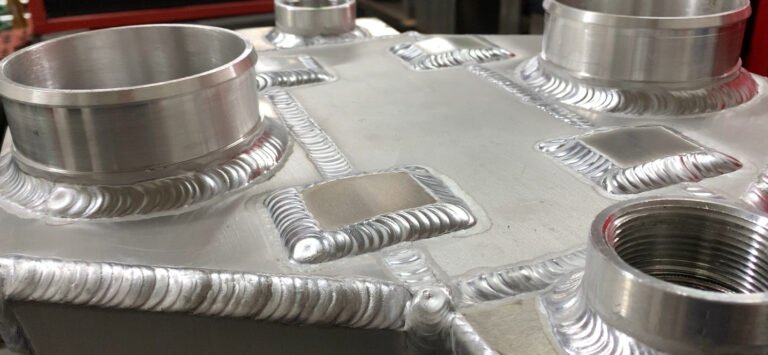

With over thirty years of experience in welding and fabrication, Heli-Arc Fabrications offers expertise in aluminum heat exchanger welding and fabrication (intercoolers, oil coolers and radiators), sign fabrication (aluminum, copper, silicone bronze, stainless and mild steels), aerospace welding (Inconel and stainless steel) and automotive welding (frame and body repairs, engine block repairs and modifications, oil pan repairs and modifications). We supply custom intercoolers and ice box reservoirs for competition tractor pulling, drag racing for off-road and street, marine applications and dyno test cells. Many of the intercoolers that we provide to our customers are for high boost applications (60-90 p.s.i. and higher).

Provide us with a sketch of your requirements and we will provide a drawing for you to approve, or if you provide a drawing we will build to your specifications.

First article and prototype projects

Heli-Arc Fabrications specializes in working with you/your engineering staff. During the development stage of your project, we will provide real time feed back to your engineers if any issues arise that might compromise your project. We do not just build it, we want it to work the way you intended it to. We understand that prototypes require a lot of back-and-forth communication to achieve the intended end result. This cooperative effort helps to minimize rework and costs due to unforeseen issues. Our team will work directly with you or your engineering staff to provide one-off / custom designed products or provide production services for your recurring projects.

Specialized Services

Heli-Arc Fabrications performs section cutting of irregular shaped items such as turbine housings or cast parts. This type of work is usually performed to inspect product for porosity, casting defects or irregularities in material thicknesses. Section cutting of this type is also utilized to display internal functions of operating parts within moving assemblies. This type of display makes for a great presentation of internal mechanisms to potential customers.

Fixture building is another service offered. Supply us a finished part and/or a drawing and we will build a fixture to suit your requirements.

For optimum weld penetration we utilize the T.I.G. welding process. M.I.G. and S.M.A.W. (stick) welding are offered as well.

No project is too small. If you are in the Los Angeles area, walk-ins are welcome.

Do you require fabrication only?

We will fabricate your components as specified by you.